Bullerjan

Bullerjan

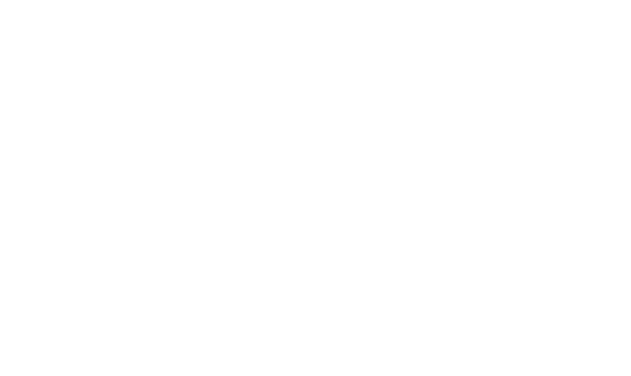

Bullerjan stove – a stove that is ideally suitable for home heating in the cold winter evenings and for keeping cosines and heat during the cold autumn season. The main advantage of such an oven is its efficiency coefficient, which accounts for the significant 80%, but the quality-to-price ratio is simply perfect.

Let’s keep the heat in your home!

PRODUCTS

QUTATION

Contact us and you don't have to wait long for a quotation or information about our products

QUALITY

Long-lasting professionally built bullerjan stove will provide you with sufficient heat in no time! 2-year warranty included!

DELIVERY

You have the option to roder delivery from us as well and save the hassle of finding a way to get the product to you!

USEFUL INFORMATION

Bullerjan type stove – a stove that is ideally suitable for home heating in the cold winter evenings and for keeping cosines and heat during the cold autumn season. The main advantage of such an oven is its efficiency coefficient, which accounts for the significant 80%, but the quality-to-price ratio is simply perfect.

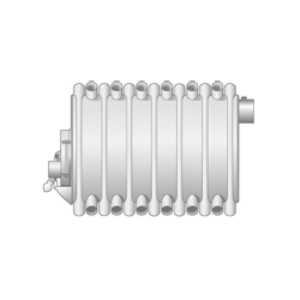

Bullerjan type stove – an all-welded steel structure that is surrounded by pipes that suck all cold air at the very floor. The air heats up very fast, as a result of which 10 minutes after the stove is lighted, the air passing through the pipes, is heated to the temperature of 80-100°C, and, flowing out of the stove, it heats the entire room. It takes only 20-25 minutes for the Bullerjan type stove, to heat a small single-store house.

These operating instructions apply to all six types and sizes of “Bullerjan” air stoves that are intended for heating residential, working and other spaces, including greenhouses and buildings under construction. Heating, ventilation and conditioning, except for A, B, C type premises where the stove – heating is not used.

Bullerjan type stove – a continuous and multi-functioning oven that works with wood and its waste and allows heating from 100m3 to 1600m3 big spaces, but with the help of air compressors it is possible also to heat some adjacent premises. Oven types and sizes differ from each other with the heat surface.

1. INTRODUCTION

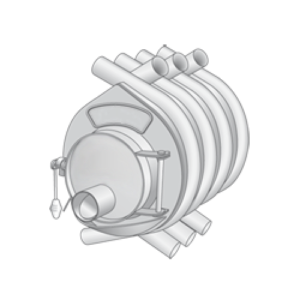

The Bullerjan calorifier furnaces are highly efficient heating equipment’s and are available in six sizes with the maximum heat output of 6 to 45 kW. The ovens can be used for heating of premises from 100m3 to 1600m3. The basic working mode is slow burning. The operating mode is chosen by the user, and it depends on the speed of reaching the required temperature and amount in the heated premises. The heated air evenly heats the room.

Before starting the installation and operation of the Bullerjan oven, you need to carefully read this operating manual.

The manufacturer’s company is not responsible for the user’s failure to comply with the rules for the installation and operation of the stove, as well as the fire safety regulations in the heated premises.

2. Performance specifications

The main technical characteristics of the Bullerjan calorifier furnace are shown in Table 1.

3. Operating principle

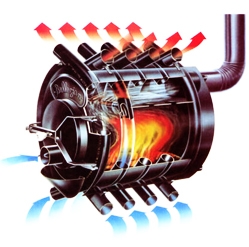

3.1. The “Bullerjan” calorifier furnace is a two-chamber heating device where with the use of the slow burning method, the fuel burning process takes place. The stove gas formed in the lower chamber (Pos. 9, fig. 1), enters the upper chamber (Pos. 7, fig. 1), where it is completely burned due to the reason that the heated air from the heated space is directed through the special injectors (Pos. 6, fig. 1).

3.2. The oven firebox is wound with heat exchanger pipes (Pos. 5, fig.1), which form an efficient heat exchanger. The cold air from the heated space penetrates into the lower openings of these pipes, but through the upper openings – it returns to the premises, having been heated up to the temperature of 80-120°C (in the slow-burning mode). In the intensive burning mode, the heated air temperature can reach 350°C. The partition (Pos.11, fig.1), which separates the lower and the upper chamber, also helps to achieve the optimal temperature in the upper openings of the heat exchanger pipes. This design of the furnace allows maximum use of the fuel combustion energy.

3.3. The fuel loading in the stove takes place through the furnace doors (Pos.2, fig.1). They are of a fairly large size, which allows loading more firewood in the stove. An eccentric door lock (Pos. 1, fig. 1) ensures the safe door closing.

3.4. The power regulator (Pos. 3, fig. 1) which can help to regulate the fuel combustion intensity, is located on the loading door. The mode for burning the oven released fuel gas is installed with a regulator – gasifier (Pos.10, Fig.1), and it is purchased each time in a trial mode depending on the quality of the funnel (Pos. 8, fig.1). The regulator- gasifier has a cut-off section to prevent the possibility of carbonous oxide penetrating into the heated premises.

3.5. The ash box (Pos. 4, fig. 1) protects against the possible fall of burning fuel particles into the floor of the room.

3.6. The large filler door and the large-volume furnace allow the use of large split firewood logs as fuel.

ATTENTION! The intense combustion mode is not the main operating mode of the stove, and it can not be recommended for continuous use, as in this case the product warranty period will be shortened and the coating of the varnish and paint will not be preserved.

4. INSTALLATION

When the stove is installed for operation, one shall comply with the technical and fire safety requirements:

4.1. The stove is used for living and administrative premises, if there are no more than two floors and no more than 25 people stay there.

5. SECURITY REGULATIONS

5.1.1. The maximum temperature for the surface of the stove’s base area in the intense combustion (heating) mode and in the low intensity combustion mode must not be higher than 90°C, but at the control unit surface – 80°C. The areas with the temperature of 110°C – 15% of the total area are and 120°C – 5% of the total area are allowed on the stove.

5.1.2. The shutter in the closed position must not be closed more than for 75% of the area of the smoke discharge pipe.

5.2. For the safe use of the Bullerjan calorifier, one shall strictly observe the requirements and recommendations set out in sections 3 and 4 of this user manual and shall observe the following requirements: Control of draught shall be carried out at least once every two months.

5.2.3. DURING THE STOVE’S OPERATING it is not allowed to :

– Ask under-aged children to take care of the stove;

– Place fuel and other combustible materials directly before the furnace outlet;

– Keep cooled coal and ash in metal containers placed on the wooden floor or on a combustible tray;

– Dry and put on the stove any clothes, firewood, other burning items and materials;

– Apply flammable liquids to light the stove; to light the stove with branches, coconut and gas;

– Use the firewood with the length greater than the furnace sizes to light the stove;

– Use ventilation and gas channels as chimneys;

– Store in the room any fuel stocks which are greater in volume than needed for one day and night;

– Use asbestos cement and ceramic pipes as smoke pipes.

6. Transportation and storage

6.1. The stove can be transported by any mode of transport in accordance with the regulations which apply to these modes of transport.

7. Warranty liabilities

7.1. The manufacturer guarantees the normal operation of the stove in accordance with its parameters and requirements, provided that the operating, transport and storage regulations are complied with, which are subject to the technical conditions and operating documents.

7.2. The guaranteed operational lifetime is determined for month. The warranty period starts with the stove sales date.

Stove putting into operations

1. Before lighting the “Bullerjan” stove, check the draught by fully opening both shutters.

2. Place paper and dry fine food (chips) and light kindling-wood. Close the filling door immediately when kindling-wood starts to burn.

3. After 5-10 minutes after lighting, close halfway the rear shutter with the regulator and set the stove operating mode with the front shutter. If the rear shutter is completely closed and the front rear shutter is minimally open, the useful efficiency of the stove will be the biggest.

4. The required burning intensity is set with the change of position of the both shutters, but the stove starts to operate in the slow-burning mode when the rear shutter is closed.

5. The angles for setting the shutters are determined experimentally and depend on the smoke outlet pipe and quality of the fuel.

Caution! DO NOT add fuel when the smoke shutter and the VALVE OF THE FRONT REGULATION are closed.

Fuel adding and ash removal

1) Before adding the fuel, switch the stove into the intense burning mode, so the both regulators must be fully open.

2) Then open the door, add fuel, close the door, and place the both regulators in the previous position.

3) Before ash removal, the fuel must be completely burned.

4) You do not need to remove ashes completely, you need to leave the ash layer of 5cm.

5) If “Bullerjan” is slow to light, it often happens in summer cottages, then the stove may not have a draught. It is necessary to check the draught.

6) It is necessary to ignite the paper when the rear shutter is closed. If the smoke does not go to the pipe, then there is no draught.

7) Having placed kindling-wood into the furnace, you need to open the cleanout box on the revision door or a T-branch, to clean it and to burn out the paper near it.

8) When the draught appears, immediately close the revision door and ignite the kindling-wood. If the chimney is made of bricks and the brick wall has cooled down, then the actions with paper will need to be repeated several times.

CONTACTS

INFO@TUBASOOJAKS.EE

Write to us. We can provide all the details you need in the form of an e-mail also

+372 54588944

Call us. You have the possibility to aqcuire information via phone call. If we don't anwser immediately, we'll get back to you as soon as possible!

Location

We are located in Estonia, a small city called Pärnu. Our address is Mere street 7

Demerest OÜ

Reg.nr 14367796

Swedbank EE292200221068110795